Lead Time :

60 workdaysRoll Forming Speed :

18-20m/minWeight :

15TModel No. :

75-200Shipping Port :

Xiamenpayment :

TT/LCAUTO Solar Panel Bracket Omega Purlin Roll Forming Machine(Economy Type)

Sample Show

Material Thickness:2.0-3.0mm

Applicable Material:GI/GL/PosMAC

Material Yield Strength:235-390 Mpa

Feeding Width:About 190-260mm

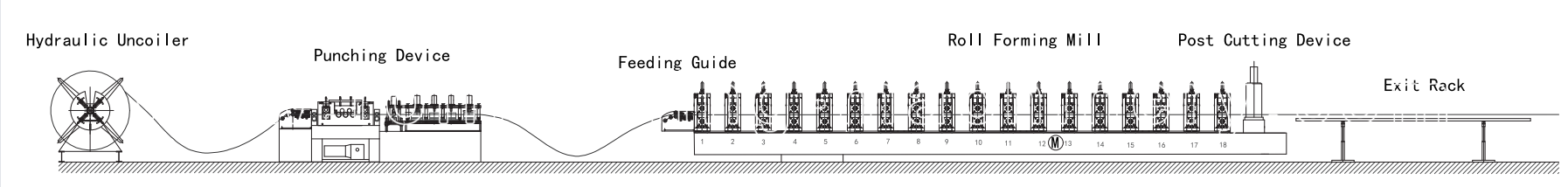

Uncoiler→Hydrualic Pre-Cutting&Punching Device→Feeding and Leveling Device→Rolling Forming System→Hydraulic Post Cutting→Exit Rack

Hydraulic control steel coil inner bore shrinkage and stop

MAX. Feeding width: 600 mm

Max capacity:5Ton

Inner diameter range of the coil: 470-560mm, outer diameter: 1500mm

Hydraulic motor: 3KW, variable frequency speed adjustment

2) Feeding and leveling device

Up three, down four, a total of seven-axis leveling device

With feed guide rail, the body frame is welded from H450 steel

Side wall thickness: Q235 t30mm

The shaft is made of GCr15 steel, diameter= φ105mm, precision machining, quenching and tempering

Use two motors to automatically adjust the feed width.

3) Hydraulic Pre-Cutting&Punching Device

Pre-punching and pre-cutting, adopts the same hydraulic system

Hydraulic motor: 18.5kW, hydraulic range: 0-25MPa (250Bar)

Material of the Punching Cutting tool: mold steel CR12MOV (= D2 steel, with a million stroke life), heat treatment to HRC58-62 degrees

Three -cylinder perforation system, punching both on Web side and Height(Flange) side.

The body frame is welded from H450 steel, and the arch structure

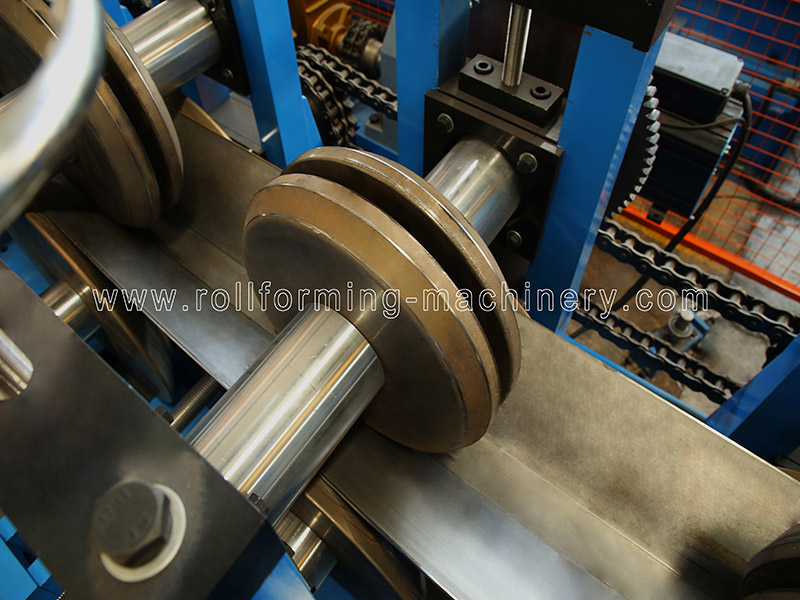

The roller is made of Cr12 steel, CNC lathe, heat treatment, HRC58-62

Shaft diameter =ф95, precision machining

Gear/sprocket drive, about 24 steps forming

Main Motor=22KW+22KW, Frequency speed control

Stop to cut, two -piece cutting design without feeding

Hydraulic motor: 18.5kW, cutting pressure: 0-16MPa

Knife material: CR12Mov (= SKD11, has at least one million cutting life), heat treatment to HRC58-62 degrees

Automatic control quantity and cutting length

Enter production data (production batch, number of production pieces, production length, etc.) on the touch screen,

Automatically complete production.

Combine: PLC, inverter, touch screen, encoder, etc.

Un-powered, One unit,with rollers on it for easy movement.

Packing method: Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),loaded into container and steadily fixed in container by steel rope and lock, suitable for long-distance transportation.

Our advantage

1.Over 25 years experience in roll forming industry,nearly 10 years of OEM experience for Taiwan roll forming machines and one of China TOP 3 high quality roll forming machinery manufacturers and exporters (BMS has exported to over 100 countries and regions).

2.Industry's best warranty in China 2 years parts & 2 years labor and 7*24 award winning customer service within 24 hours.

1. The warranty is 24 months after the client receives the machine.Within the 24 months, we will courier the replacement parts to the client free of charge.

2. We offer technical support for the entire life of our machines.

3. We can send our technicians to install and train the workers in the clients' factories with extra cost.

1.Minimum order quantity (MOQ): 1 Set.

2.Delivery time: about 60 workdays.

3.Port of loading: port of Xiamen.

4.Type of payment: by T/T or by L/C.

5.Export:to more than 100 countries and regions, including Taiwan, UK, France, Singapore,

Greece, Australia, USA, Mexico, Brazil, Chile, Bolivia, Trinidad, Israel, Saudi Arabia, etc.